This young company won the 2018 EPHJ Exhibitors Grand Prix for its process for bonding glass to ceramics and metals at low temperatures. Two years later, its AdHera patent is tackling thin films.

By Joël A. Grandjean

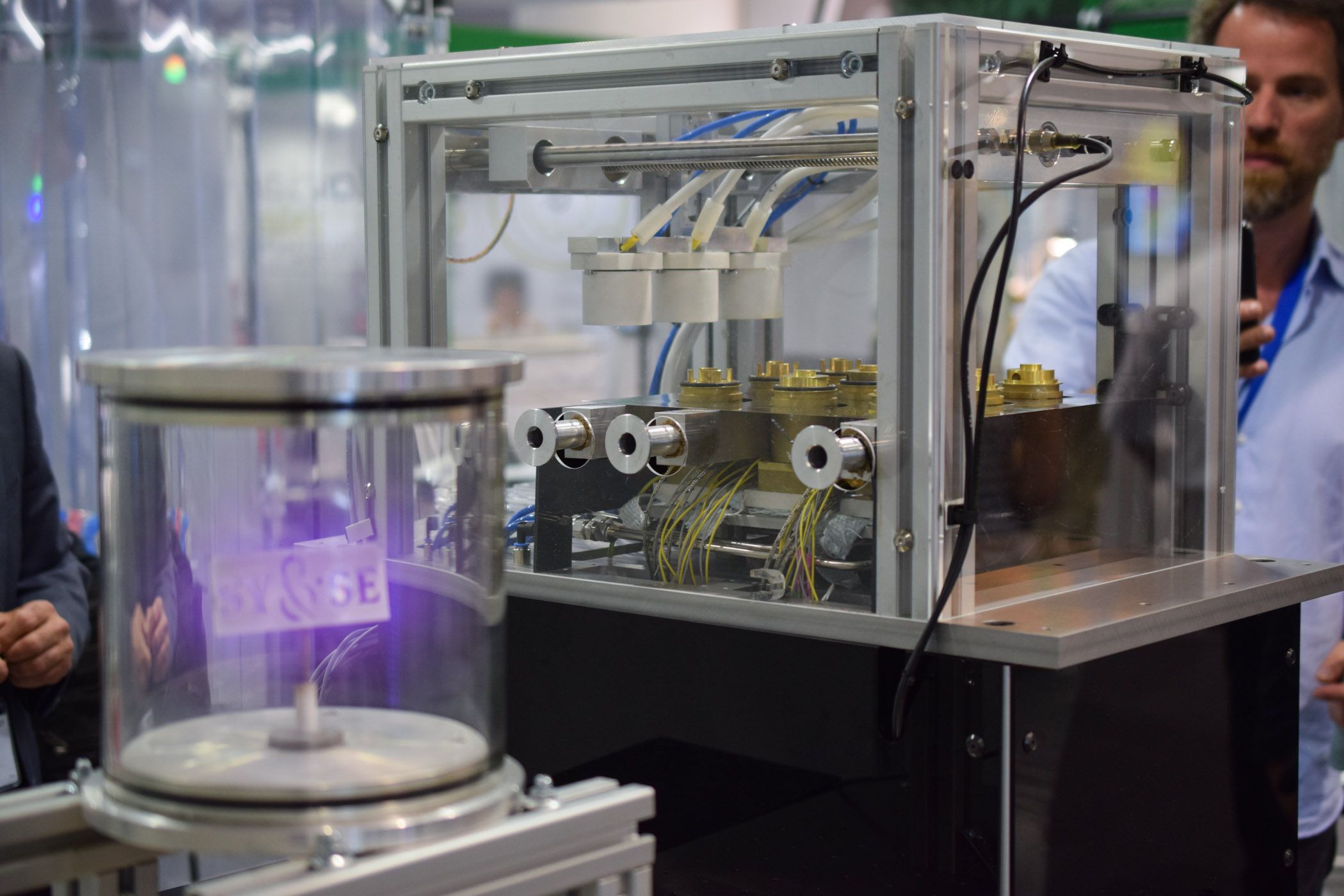

A new patent! This start-up from the Haute Ecole Arc Ingénierie (HE-Arc) is continually innovating – and sticking to its guns. After working with its ICB (Impulse Current Bonding) technology to expand its metal-glass-ceramic innovation to include new metals such as aluminium, spinel and surgical titanium, the company has now submitted another patent application for a new physicochemical process, this time to solve a recurring problem in watchmaking and associated industries: bonding thin layers.

Optimised bonds with AdHera

Thin layers include all those micro-coatings that cover watch components and watch housings: PVD, ALD and electroplating that embellish and protect. AdHera, a patented low-temperature (150 °C) technology, orchestrates the migration of ions by applying an electrode and managing energy.

The result is a new material, created without any contact, that considerably strengthens the final bond to the part. The bond at the point of contact between the substrate – currently only steel as far as this new patent is concerned – and the coating is greatly enhanced. The ions migrate and restructure, as if the two materials are interacting until they merge into each other, creating a third material somewhere between the two.

Major potential in multiple industries

The method is currently focused on small components until it can be expanded to larger and more complex surfaces such as entire watch housings. It offers the benefit of perfecting the bond, thus ensuring coating integrity in case of bending or impact.

At the company’s headquarters in Chaux-de-Fonds, Switzerland, a series of vigorous and merciless tests have confirmed the inventors’ assumptions. They were assisted by well-established firms such as Presi Sàrl which helped them install the machines and prepare the surfaces. This enabled them to validate their claim that, when subjected to a 180-degree bend, a batch of parts conventionally coated with thin layers of titanium nitride (TiN) showed far better resistance after being treated with AdHera technology.

Sy&Se Microsystem Technologies has already been approached by watchmaking and medtech customers as well as players in the cutting tool industries. Why? Because this patented process can be applied after conventional treatments. It’s easy to do and not unreasonably expensive.