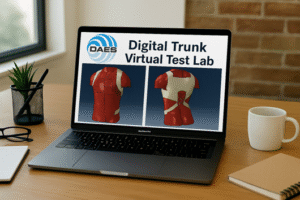

Lower back pain affects up to 75% of the adult population: a true modern scourge. Confronting this public health challenge, DAES SA, based in Petit-Lancy, is developing a digital model of the human torso to precisely simulate biomechanical interactions between medical devices and the human body.

Their approach, aligned with international validation standards (ASME V&V40), optimises device design in the preclinical phase by reducing reliance on lengthy and costly physical testing. Continuously enriched, this digital torso anticipates complications, evaluates mechanical performance, and supports personalized rehabilitation strategies. It marks a new era in Medtech design—one where technology serves prediction, safety, and above all, tangible patient benefit.

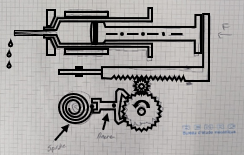

Who would have thought that a spring inspired by watch barrels could find its place in a medical device? That is the bold innovation of BEMRC SA, the engineering firm based in Noës/Sierre, which has unveiled a fully mechanical syringe driver capable of ensuring continuous infusion through a winding mechanism.

With no battery or backup power supply, this system relies entirely on mechanical energy, offering a simple, robust and reliable solution in constrained or critical environments. Elegant yet functional, this innovation sits at the crossroads of watchmaking and healthcare, paving the way for autonomous, precise medical devices—ideal for responding to power outages or operating in regions with limited energy resources.

These two projects, along with the other finalists to be presented in the next edition, will benefit from tailored support by the Inartis Foundation—from prototype development to market access and industrialization.

The Watch Medtech Challenge is not just another competition. It is a showcase of unique Swiss know-how, capable of transforming centuries-old watchmaking principles into tomorrow’s healthcare solutions. And when these ideas take shape, the entire ecosystem—patients, clinicians, engineers—stands to gain.