CMT RICKENBACH – Photochemical machining: a highly delicate process for flat workpieces

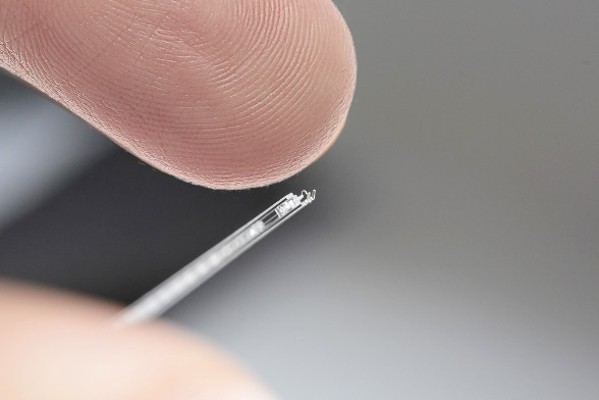

CMT RICKENBACH – Photochemical machining: a highly delicate process for flat workpieces Published on mars 20, 2025 Photochemical machining is a technology of choice for machining and engraving metal workpieces, but one that is only used if these pieces are flat. We interviewed Thomas Rickenbach from CMT Rickenbach to find out about what this process involves and its benefits. Photochemical machining (PCM) is a combination of photolithography and etching. This process allows metal strips to be turned into flat pieces with a complex geometry at a high resolution. It is mainly used in the electronics, aerospace and medical sectors and by luxury goods manufacturers, given that a wide range of materials can be machined: different steel types (especially 316L stainless steel), different copper types, tungsten, titanium and molybdenum, among others. The stages of the process An ophthalmic scalpel (photo credit: CMT Rickenbach) The first stage, and also clearly among the most important, is the preparation of the material. The plates pass successively through a number of surface preparation baths (degreasing and deoxidation of the base substrate) in order to optimise adhesion and correctly prepare the material for the etching stage. The next stage is application of the photosensitive coating. There are two main techniques for doing this: deep coating, for applying liquid resin in applications which generally require greater precision; and hot lamination with solid resin. Once the material is coated, the plate is exposed to ultraviolet (UV) light with a photographic tool including the negative of the piece for machining. UV rays have the effect of polymerising the photosensitive resin. We thus end up with a hard piece, designed to resist the etching agent that will subsequently be used to machine the pieces, and an unpolymerised part of the resin which will have to be removed. ENVIRONMENT Concern for the environmentAsked how CMT reconciles its photochemical machining activity with environmental protection, Thomas Rickenbach replies: “The use of chemicals inevitably entails protective measures.” CMT Rickenbach has two main measures to protect the environment from its chemicals: recycling of its active agent: used in a closed circuit, it is reactivated using electrolysis treatment; the treatment of all the water used for its chemistry, carried out in a treatment plant. At the same time, the company has taken other steps, such as recycling the packaging and chemicals it uses. It also plans to fit out its installation with solar panels in the future. Thomas Rickenbach, son of the head of CMT Rickenbach, is a methods engineer at the family firm, standing it in good stead to hand over the reins to the next generation (photo credit: CMT Rickenbach). Now there are also direct imaging machines which ‘draw’ the parts to be polymerised directly on the resin, using a collimated beam of light, which makes it possible to dispense with the actual photographic tool. Then the plates are immersed in a development solution, which removes the uncured parts of the photosensitive coating, thus revealing the areas of metal to be engraved. These three operations (lamination, exposure and development) are carried out in a clean room in order to protect production from particles and dust which could leave artefacts on the plates when exposed to UV light. There is also the need to protect the plates from natural UV light (from the sun). We now come to the machining/engraving stage. The plates are immersed or sprayed with acid (using a bath or conveyor). This is followed by an oxidation-reduction reaction, during which the etching agent will dissolve the metal. Given that the resin is resistant to the etching agent, machining is carried out selectively. As metal dissolution is isotropic, there is a need to machine the plate on both sides in order to machine the pieces. Hence the thinner the plate, the greater the precision (±5 µm for a 10-µm thick plate, for example). Conversely, the thicker the plate, the greater the tolerance range must be (for instance, for a thickness of 2 mm, the tolerance is ±100 µm). Finally, all that remains is to remove the protective resin to reveal the piece and, finally, to clean and rinse the piece to eliminate all chemical residues. Why choose photochemical machining?Apart from its precision, photochemical machining has the major advantage of enabling clean and burr-free machining: as the metal is dissolved by oxidation-reduction, the material is neither deformed nor thermally altered. A medical saw blade produced using photochemical machining Photo credit: CMT Rickenbach Bildnachweis: CMT Rickenbach This holds for both softer and very hard metals, which can be machined in the same way. This is a significant advantage compared with a stamping process, which will heat up the material and cause deformations there. In addition, because the photographic tool is easy to produce and inexpensive, this technology is ideal for prototyping or small to medium-scale production. It also allows for great design flexibility and rapid responsiveness. For small pieces, it is easy to place a lot of them on the same thin plate. This makes it possible to produce a very large number of pieces with high precision and at a speed, and therefore a price, that could not be achieved using laser cutting technology. Photochemical machining, laser and electroplating technologies mean that CMT Rickenbach boasts a high level of flexibility in producing its customers’ pieces, but also a high degree of control over the subcontracting chain. Of course, PCM also has its limitations. It is a 2D engraving process, which means that it is mainly used for flat pieces. Although slight reliefs are possible, this process is not suited to pieces requiring complex three-dimensional shapes. “The rule is always to marry the right technology with the right pieces,” concludes Rickenbach. You can find CMT Rickenbach at stand Q89 at EPHJ 2025! Discover Precitrame Share this article Facebook Twitter Youtube News 25 avril 2025 Emissa dévoile le Precimill, un centre d'usinage compact et performant 25 mars 2025 Medtech – a rapidly expanding part of the EPHJ Show 20 mars 2025 CMT RICKENBACH – Photochemisches Ätzen: ein subtiles Verfahren für flache Bauteile 20 mars 2025 WatchDec – die Hochpräzision im Dienst