FEMTOPRINT – Microscopic glass parts harnessed for the purposes of medical innovation

- Published on the March 20, 2025

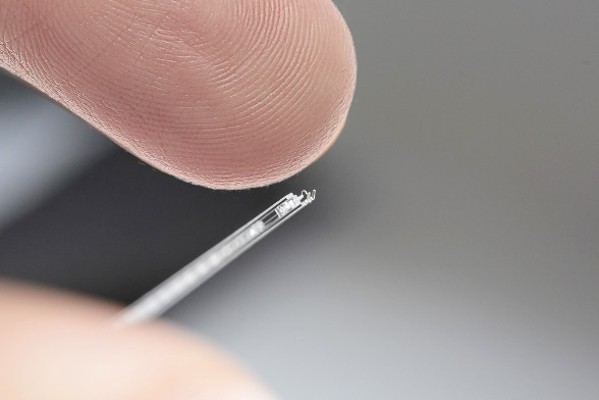

FEMTOprint uses fast and precise laser technology to produce complex tiny glass structures. The Swiss company can thus offer customised solutions enabling the development of next-generation medical devices which are smaller, smarter and more efficient.

Miniaturisation is a consistent trend in medical device manufacturing, driven by the need for less invasive procedures, portable diagnostics and implantable technologies. FEMTOprint’s micron-level precision in the field of glass manufacturing addresses this need by enabling the production of miniaturised, three-dimensional components that would be impossible or very difficult to achieve using traditional manufacturing methods. Whether developing microfluidic systems or implantable sensors or integrating optical components, the company assures its customers that its technology will optimise performance and reliability.

Customised solutions for miniaturised medical devices

FEMTOprint found that miniaturisation projects require tailored solutions and advanced expertise to meet specific design and functionality requirements. For more than 11 years, the company has been working closely with medical device manufacturers, providing comprehensive support from design and prototyping through to large-scale production. This collaborative approach ensures that miniaturised devices not only meet expectations, but exceed them.

Whether developing a lab-on-a-chip platform for rapid diagnosis, a miniaturised implant requiring the encapsulation of microelectronics for targeted therapy, or an advanced imaging system, FEMTOprint technology is proving a real driver of innovation.

Applications marked by innovation

FEMTOprint technology is driving advances in a wide range of miniaturised medical applications:

- Microfluidic devices: FEMTOprint’s glass chips enable precise fluid control at microscopic scale, making them suitable for applications such as point-of-care diagnostics. These devices are transforming disease detection, drug discovery and personalised medicine.

- Implantable devices: FEMTOprint’s biocompatible glass sensors are revolutionising patient monitoring by providing real-time data on critical parameters such as intra-ocular, arterial or intra-cranial pressure. Designed for long-term implantation, these sensors ensure reliable performance in demanding environments. They can be made from composite materials, mixing for example silicon and fused silica.

- Optical components: With extreme precision, FEMTOprint can integrate lenses, waveguides and complex micro-mechanical architectures to hold optical fibres, thus enhancing medical imaging and diagnostics. From endoscopic systems to Raman spectroscopy, these components offer unparalleled clarity and precision, promoting optimised diagnosis and treatment.

- Drug delivery systems: The micro-arrays of needles, implants and glass microfluidic systems developed by FEMTOprint enable targeted and controlled drug delivery. These solutions are particularly useful for applications such as cancer therapy, chronic disease management and vaccine delivery.

Accelerating innovation through rapid prototyping

In the dynamic world of medical device manufacturing, speed is vital. FEMTOprint’s rapid prototyping capabilities enable the fast iteration and refinement of device designs, reducing development cycles and accelerating time to market.

Additionally, FEMTOprint’s platform offers design flexibility at all stages of product development, including late modifications, while promising an extremely limited financial impact.

A collaborative partnership for cutting-edge solutions

As well as being a subcontracting manufacturer, FEMTOprint is a strategic partner for medical device manufacturers wishing to push the limits of miniaturisation.

By combining its technical expertise with a deep understanding of the challenges facing the sector, the company helps its partners navigate the complexity of device development, in particular in areas such as selective metal deposition, and bring innovative solutions to market by enhancing components and systems with additional functionalities, such as droplet generation.

Shaping the future of miniaturised medical devices

As the demand for miniaturised medical devices continues to grow, FEMTOprint is positioning itself at the forefront of emerging trends such as AI-powered diagnostics, multifunctional implants and smart medical devices.

The company is anticipating these developments, rather than simply meeting manufacturers’ current needs: its ambition is to actively contribute to shaping the future of healthcare.

You can find FEMTOprint at stand M74 at EPHJ 2025!