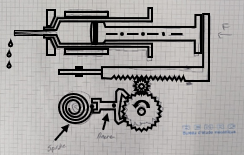

More compact, PX calibres transcend the Sphérillon

More compact, PX calibres transcend the Sphérillon Published on 15 December 2025 The horological UFOs known as Sphérillon—a contraction of “sphere” and “tourbillon”—are undergoing a revolution: now more compact, promising additional functions, and even capable of evolving into automatic calibres. The most avant-garde watch brands are set to experience new, improbable thrills. Under the name PX, the art of the tourbillon enters a new dimension. At EPHJ 2025 First unveiled in Geneva in 2022 at the high-precision trade show by Purtec, the company of “crazy movements” founded in 2021 in Vallorbe by Arnaud Faivre and integrated into the Tec-Group Swiss, this invention by master watchmaker and Gaïa Prize laureate Éric Coudray now opens up fresh applications. “Talented designer and master watchmaker Éric Coudray named his tourbillon ‘Sphérillon’ to simply define its main technical specificity,” noted journalist and watchmaker Vincent Daveau in a Swiss horology journal. He recalled that “in 1801, Abraham-Louis Breguet also christened his cage ‘tourbillon,’ as it performed a regular rotation to cancel out balance defects of the regulating organ inside—because once the watch was running, the component seemed to whirl.” A Concentration of Feats Inspiring Creativity Rarely has a mechanical calibre embodied such a blend of enchantment, kinetics, chronometric complexity, and precision. Now, under the PX designation, the celebrated Sphérillon has been reduced in size, making it more accessible for those returning to the design of timepieces with more “reasonable” dimensions—aligned with the global trend back to 40 mm diameters, or even smaller. This roadmap also brought an inevitable gain in reliability thanks to fewer components overall. Notably, the thickness remains at 9.46 mm—even in “full options” versions—and the 50-hour power reserve is still guaranteed. ‘A calibre housed in a case that stays true to the current trend of watches returning to around 40 mm in diameter, with a tonneau and square shape.’? Photographer and graphic artist Jérôme Saillard has demonstrated through case studies that countless combinations are possible. “The mainplate has been optimized to optionally integrate additional functions: two options for power reserve display (at 6 o’clock or 4 o’clock), the addition of a seconds hand aligned with the off-centered hour track while preserving clear legibility of the hour and minute hands, and not forgetting the automatic winding system,” explains Bastien Maillefer, Purtec’s head of watchmaking. Prestigious brands lining up Under the PX designation, these evolutions of the Sphérillon are hyper-complex micromechanical constructions, already being tested for months on the wrists of Purtec’s watchmakers. There is little doubt that this vast territory of new technical and aesthetic possibilities will soon inspire the most prestigious houses of haute horlogerie to create pieces that go far beyond mere “talking pieces.” https://purtec-movements.com PX Purtec calibres 21,600 vph, technology and materials With reduced diameter and thickness, the PX calibres fit seamlessly into tonneau cases (32.8 mm from 3–9h and 34.3 mm from 12–6h), as well as square or round designs. The rotation speed of the titanium outer cage of the tourbillon remains at 30 seconds, ensuring extraordinary visual appeal. To achieve greater inertia despite the smaller size, the balance arms and weights are crafted in solid gold. Meanwhile, the outer terminal curves of the Breguet spirals at the heart of these calibres—beating at 3 Hertz, or 21,600 vibrations per hour—are shaped internally in the “Philips” style. Joël A. Grandjean / 1876 News Sienna Private Equity joins TEC Group On October 17, 2025, TEC Group, founded in 2008 by Arnaud Faivre, announced the entry of Sienna Private Equity (SPE), a European mid-market private equity fund, as an investor. The transaction coincides with the acquisition of AMC Technologies, a leader in precision tool manufacturing. The combined group will be led by Arnaud Faivre and Stéphane Vagne. TEC Group is a recognized supplier to Switzerland’s luxury watch industry, specializing in the production of essential components for mechanical movements and partnering with some of the most prestigious watchmaking houses. With SPE’s backing, TEC Group aims to accelerate its growth trajectory—both organically and through strategic acquisitions—while expanding the range of services offered to its clients. News 15 December 2025 More compact, PX calibres transcend the Sphérillon 15 December 2025 Innovation Digest EPHJ 2025 – The Future of High Precision, Down to the Micron! 15 December 2025 Best wishes ! 15 December 2025 Strategic acquisition in the world of custom packaging Show all news Facebook Twitter Youtube Share this article